Company Advantages

· Meenyon hydrogen forklift has been verified to meet various quality requirements. It has been tested to work properly under various conditions, even harsh conditions.

· In order to meet its set industry standards, the product is subject to strict quality control throughout the production process.

· In the fierce market competition, it gradually shows strong competitiveness.

10kw Liquid Cooled Fc Stack Vl-Series

Additional Information

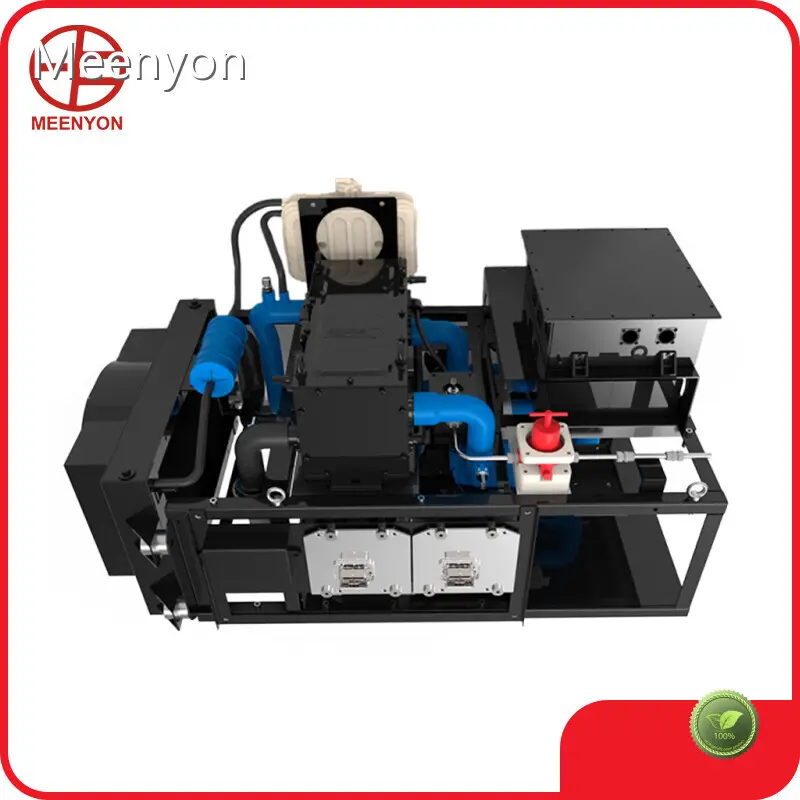

As with other liquid cooled fuel cell stacks, this fuel cell stack is considerably heavier than air cooled stacks. The following items are often included with a liquid cooled fuel cell stack from Horizon: an air filter, air flow meter, hydrogen intel solenoid valve, humidifier, throttle valve, radiator, ion exchange, controller, fuel cell stack, fill water tank, fuel cell 24V water pump, constant voltage DC, and blower to bring air into the fuel cell stack.

Please submit a quote request form in order to obtain additional information about this product. This will also provide you with an opportunity to provide details on the project you are working on that needs a fuel cell stack, and with that additional information we may be able to recommend other components you will need to expedite the completion of your project.

List of VL-10 components and their functionality

◆ Air filter (Prevents damaging size particles from entering fuel cell)

◆ Air flow meter (Monitoring feedback of air flow)

◆ Humidifier (Adds humidity to the air entering the stack)

◆ Radiator (Removes excess heat from the system)

◆ Ion Exchange (Absorbs ions in the coolant and reduce the conductivity of the coolant)

◆ Controller (Control system, system and vehicle communication)

◆ Fuel cell stack (Oxygen and hydrogen react to produce power)

◆ Fill water tank (Filling water and purge air for the fuel cell system)

◆ Fuel cell 24V water pump (Powers the cooling cycle of the fuel cell)

◆ Constant voltage DC (Charge the 48V power battery)

◆ Blower (Provide air for the system)

In addition to the above components, the fuel cell system is also equipped with some sensors to feed back the temperature, pressure and humidity signals of the controller system during operation.

The internal oxygen supply system and cooling system components of the system also need to be connected with silicone tubes and multi-way joints to ensure the flow of fluids in the system.

The fixing of the various parts of the system requires the support of a bracket, and the whole system needs a fixed frame, which is connected and fixed together by the frame. Finally, many electrical parts in the system need to be connected with high-voltage wiring harness or low-voltage wiring harness.

10kW Liquid Cooled FC Stack VL-Series Quick Product Facts

Packing Information

|

VL-05 |

VL-10 |

VL-30 |

VL-40 |

VL-65 |

VL-100 |

VL-120 |

|

||

|

System rated power output (kW) * |

5 |

10 |

30 |

40 |

65 |

100 |

120 |

*does not include cooling fan power and boost DC efficiency |

|

|

Stack rated power output (kW) |

6 |

12 |

36 |

53 |

79 |

120 |

150 |

|

|

|

Number of cells |

65 |

90 |

150 |

220 |

330 |

500 |

500 |

|

|

|

Operating ambient temperature (℃) |

-10 to +40 |

-10 to +40 |

-30 to +45 |

-30 to +45 |

-30 to +45 |

-30 to +45 |

-30 to +45 |

|

|

|

Storage ambient temperature (℃) |

-40 to +60 |

-40 to +60 |

-40 to +60 |

-40 to +60 |

-40 to +60 |

-40 to +60 |

-40 to +60 |

|

|

|

Operating ambient humidity (%) |

0 to 95 |

0 to 95 |

0 to 95 |

0 to 95 |

0 to 95 |

0 to 95 |

0 to 95 |

|

|

|

Operating pressure (kPa) |

up to 50 |

up to 50 |

80 to 100 |

80 to 100 |

80 to 100 |

80 to 100 |

120 to 150 |

|

|

|

IP rating |

IP54 |

IP54 |

IP67 |

IP67 |

IP67 |

IP67 |

IP67 |

|

|

|

Vibration noise (dB) |

up to 80 |

up to 80 |

up to 78 |

up to 78 |

up to 78 |

up to 78 |

up to 90 |

|

|

|

Voltage current output |

125A@48V |

222A@54V |

400A@90V |

400A@132V |

400@198V |

400@300V |

500A@300V |

|

|

|

System dimensions (mm) ** |

630 x 560 x 610 |

630 x 560 x 610 |

742 x 686 x 637 |

890 x 600 x 520 |

970 x 600 x 516 |

1200 x 790 x 520 |

1200 x 680 x 630 |

** radiator, touch screen, booster DC or air compressor not included |

|

|

System weight (kg) *** |

170 |

180 |

135 |

145 |

170 |

238 |

290 |

*** booster DC not included |

|

|

DC output voltage (V) |

48 |

48/80 |

|

|

|

|

|

|

|

|

Boost DC output voltage (V) |

|

|

300 to 450 |

500 to 700 |

500 to 700 |

500 to 700 |

500 to 700 |

|

|

|

System mass power density (W/kg) **** |

|

|

220 |

275 |

382 |

420 |

505 |

*** booster DC not included |

|

|

Fuel cell stack volume ratio power (kW/l) |

|

|

|

|

|

|

3.5 |

|

|

|

Stack operating temperature (℃) |

60 to 70 |

60 to 70 |

70 to 85 |

70 to 80 |

70 to 80 |

70 to 80 |

70 to 85 |

|

|

|

H2 purity (% dry hydrogen) |

99,97 |

99,97 |

99,97 |

99,97 |

99,97 |

99,97 |

99,97 |

|

|

|

Average H2 consumption at rated power (m3/kWh) |

|

|

up to 0,73 |

up to 0,73 |

up to 0,73 |

up to 0,73 |

up to 0,73 |

|

|

|

Fuel Cell efficiency at rated power (%) |

at least 42 |

at least 42 |

at leas 47,8 |

at least 47,8 |

at least 47,8 |

at least 47,8 |

at least 47,8 |

|

|

|

Hydrogen inlet pressure (Mpag) |

0,6 to 1.0 |

0,6 to 1.0 |

1,1 to 1,3 |

1,1 to 1,3 |

1,1 to 1,3 |

1,1 to 1,3 |

1,1 to 1,3 |

|

|

Company Features

· Meenyon has built our reputation as a reliable provider of hydrogen forklift, serving the China market over the past years.

· Meenyon has scientific management mode and well-trained talented employees. Meenyon has a number of large-scale production lines.

· Meenyon is qualified as the most competitive hydrogen forklift manufacturer.

Product Details

Meenyon adheres to the principle of 'details determine success or failure' and pays great attention to the details of hydrogen forklift.

Application of the Product

The hydrogen forklift produced by Meenyon has a wide range of applications.

Our company will modify and adjust the original solution according to the customer's needs. By doing so, we can provide solutions that best meet the customer's needs.

Product Comparison

We demand ourselves in the production of hydrogen forklift with stricter standards. Based on this, we ensure that our products have advantages over the general products in the following aspects.

Enterprise Advantages

Meenyon attaches great importance to talent cultivation. Currently, we have an excellent and efficient staff team who effectively guarantees sustainable development.

Meenyon owns a comprehensive after-sales service system and information feedback channels. We have the ability to guarantee comprehensive service and effectively solve customers' problems.

Meenyon always insists on building the brand with quality and developing the business with innovation. We comply with the enterprise spirit to be rigorous, efficient and enterprising. While attaching importance to brand building, we stick to sustainable development. Our commitment is to provide quality products and caring services wholeheartedly.

Meenyon was founded in Having explored and developed for years, we are a leading company in the industry with large business scale and strong business strength.

The products that we provide are not only sold well to the domestic market, but also to some countries and regions like Europe, North America and Australia. And the products are favored by lots of customers overseas.